首页 » GIS Bushing

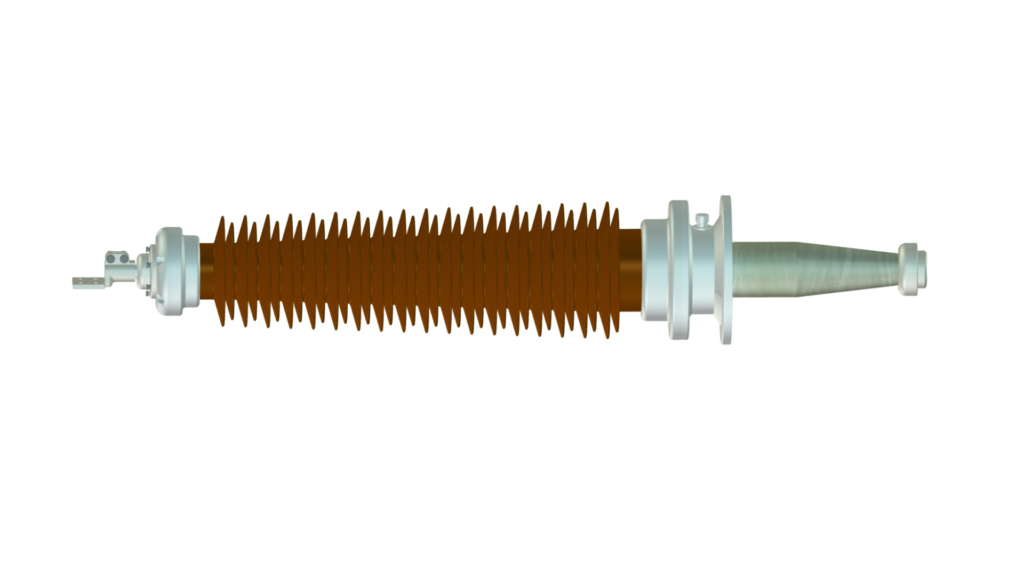

GIS Bushing

A GIS bushing is a critical component in Gas-Insulated Switchgear (GIS) systems, which are used in high-voltage electrical transmission and distribution. These bushings are designed to allow conductors to pass through the GIS enclosure while maintaining insulation, using SF6 gas to prevent arcing and ensure electrical integrity.

GIS Bushing Product Series

Implementation Standards: GB/T 4109-2022 and IEC60137

Production Range: rated voltage 72.5kV-363kV, rated current 1250A-4000A.

Partial Discharge at Rated Voltage: ≤10pC

Dielectric Loss at 1.05 Times the Highest Phase Voltage: ≤0.4%

GIS bushing consists of dry capacitor core, flange, pure porcelain, equalizing ball, terminal block, etc.

The main insulation is the principle of capacitor series voltage division. The product quality is ensured through scientific field strength calculation, design and strict process execution.

This type of bushing is a pure dry product. The bushing is not filled with oil or gas. It has many advantages such as maintenance-free, small size, light weight, simple structure and high mechanical strength. The product is widely used in substations, power plants, metallurgy, coal, petroleum and other fields, and the product is in good operating condition.

Implementation Standards: GB/T 4109-2022 and IEC60137

Production Range: rated voltage 72.5kV-363kV, rated current 1250A-4000A.

Partial Discharge at Rated Voltage: ≤10pC

Dielectric Loss at 1.05 Times the Highest Phase Voltage: ≤0.4%

GIS bushing consists of dry capacitor core, flange, silicone rubber, voltage-equalizing ball, terminal block, etc.

The main insulation is the principle of capacitor series voltage division, and the product quality is ensured through scientific field strength calculation, design and strict process execution.

This type of bushing is a pure dry product, with no oil or gas inside the bushing. It has many advantages such as maintenance-free, small size, light weight, simple structure and high mechanical strength. The product is widely used in substations, power plants, metallurgy, coal, petroleum and other fields, and the product is in good operating condition.

Frequently Asked Questions

The tail end is replaced. If the surface is not scratched 0.5mm deep, the surface burrs can be polished off with fine sandpaper. The depth is greater than 1mm. Damage that cannot be repaired by naked eye observation should be returned to the factory for repair or repurchase.

Retest according to the test report and test method. For example, connect 10kv directly, place the bushing on the insulating bracket or suspend it with an insulating rope, or replace the test equipment of different manufacturers, and contact the after-sales staff to jointly investigate the cause.

The end screen of the bushing is damp, and it should be placed in a dry and ventilated environment, or dried. It is recommended to be 80 degrees *6h, and it will return to normal levels.